Leave Message

Shenghua Crane Video

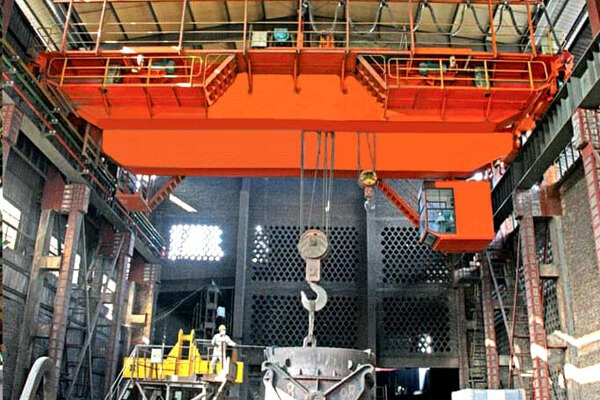

Overhead Crane for Metallurgy

Lifting Capacity: 30~100t

Span: 19.5~28.5m

Lifting Height: 20/22m, 28/32m

Working Class: A6, A7

Product Overview

Overhead Crane for Metallurgy is mainly used for transporting, pouring and charging hot metal in the process of smelting liquid metal, etc.

According to the crane structure, the ladle overhead cranes can be classified into Double Girder Double Rail Ladle Cranes, Four Girder Four Rail Ladle Cranes, and Four Girder Six Rails Ladle Cranes.

Main lifting mechanism of this Metallurgy Overhead Crane can lift goods with fast speed to meet the requirement of efficient production. Advantages of Metallurgy Overhead Crane: safe and reliable, advanced tech, solid structure, economical, long service life and convenient to maintain etc.

Product Specifications

|

Capacity

|

T

|

32/5,50/10

|

|||||||

|

Span

|

m

|

10.5

|

13.5

|

16.5

|

19.5

|

22.5

|

25.5

|

28.5

|

31.5

|

|

Lifting height

|

m

|

16/18

|

|||||||

|

Lifting speed

|

m/min

|

15.6

|

|||||||

|

Trolley travelling speed

|

m/min

|

3.36-33.6,2.9-29

|

|||||||

|

Crane travelling speed

|

m/min

|

92.7

|

93.7

|

86.5

|

|||||

|

Total weight

|

kg

|

15406

|

17290

|

20020

|

21724

|

24213

|

28579

|

31970

|

35389

|

|

Max. Wheel load

|

KN

|

104

|

111

|

120

|

125

|

132

|

144

|

152

|

162

|

|

Rail recommended

|

Model

|

43kg/m

|

|||||||

|

Total motor power

|

kw

|

27.8

|

31.8

|

||||||

|

Main dimension (mm)

|

Span(m)

|

10.5

|

13.5

|

16.5

|

19.5

|

22.5

|

25.5

|

28.5

|

31.5

|

|

Rail top to crane top

|

H

|

1750

|

1840

|

||||||

|

Rail top to hook center

|

H4

|

55

|

5

|

||||||

|

Crane base distance

|

W

|

5140

|

5334

|

5940

|

|||||

|

Crane width

|

B

|

3450

|

4400

|

||||||

|

Trolley rail distance

|

K

|

1400

|

|||||||

|

Hook left limitation

|

S1

|

800

|

|||||||

|

Hook right limitation

|

S2

|

1250

|

|||||||